Drag Racing Specialties

Innovators not Imitators

Plano, Texas Madison, Mississippi

bherrick@slotcar.com

Drag Racing Specialties Tube/Wire Chassis Kits

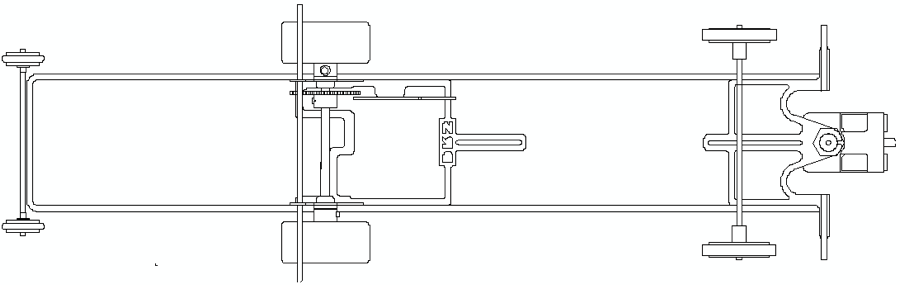

The chassis are shown completely assembled from the instruction sheets for clarity.

This is not the way that we sell them.

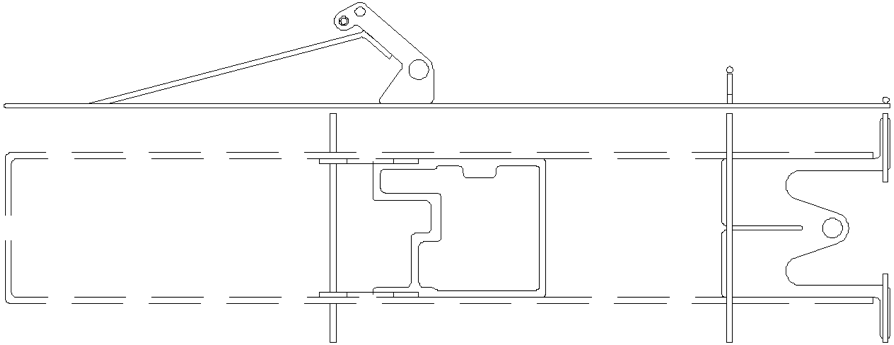

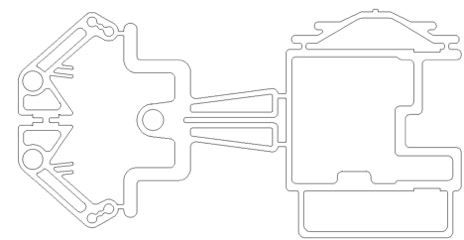

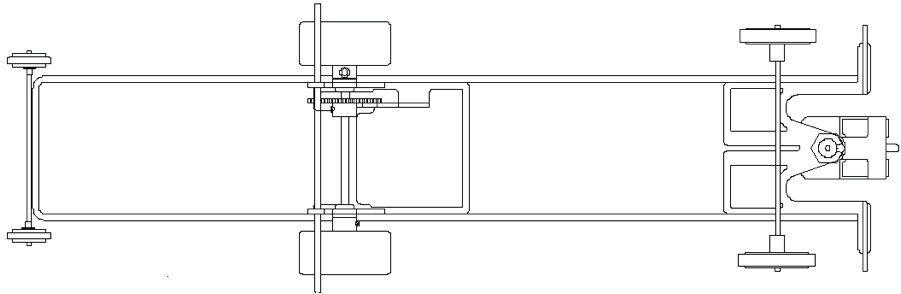

DRS-166 Full Sidewinder Doorslammer Wire Chassis Kit

Clears up to a 58 tooth gear! Assembly Options and Instructions The new DRS-166 is a highly adaptable chassis kit, and can be built in a large number of variations. Before assembly, review the following body mount and configuration options: We also recommend using DRS-161 Chassis Tubing to build your new chassis. This tubing has been used by Bob Herrick since 1987! It IS what is used by the fast crowd. Front Mount – Depending on body type and personal preference, the front of the body may be mounted at two points straight off the front, to the sides of the nose (as shown), or to the axle tube where it meets the body wheel well. Rear Mount – The rear of the body may be mounted with a solid or “floater” tube at the chassis balance point, at the forward, higher upright hole, or the slightly lower rear hole (as shown). Holes are large enough to permit proper “float” with either .050” or .062” tubing.

Wheelie Bar Braces – While not necessary for most C-Can motor applications, some motors (e.g., Top Gun or cobalt) or your personal preference may require wheelie bar braces (DRS-146 .050 pin tubing is recommended) can be fitted to the radius under the rear mount (as shown).

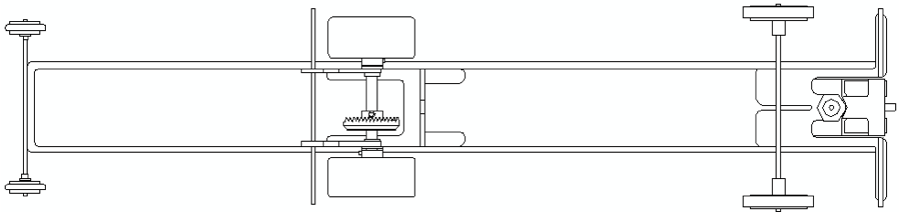

DRS-167 Full Sidewinder Altered/ F/C Wire Chassis Kit

Clears up to a 58 tooth gear! Assembly Options and Instructions The new DRS-166 is a highly adaptable chassis kit, and can be built in a large number of variations. Before assembly, review the following body mount and configuration options: We also recommend using DRS-161 Chassis Tubing to build your new chassis. This tubing has been used by Bob Herrick since 1987! It IS what is used by the fast crowd. Front Mount – Depending on body type and personal preference, the front of the body may be mounted at two points straight off the front, to the sides of the nose (as shown), or to the axle tube where it meets the body wheel well. Rear Mount – The rear of the body may be mounted with a solid or "floater" tube at the chassis balance point, at the forward, higher upright hole, or the slightly lower rear hole (as shown). Holes are large enough to permit proper "float" with either .050" or .062" tubing.

Wheelie Bar Braces – While not necessary for most C-Can motor applications, some motors (e.g., Top Gun or cobalt) or your personal preference may require wheelie bar braces (DRS-146 .050 pin tubing is recommended) can be fitted to the radius under the rear mount (as shown).

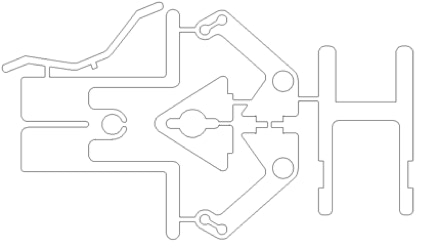

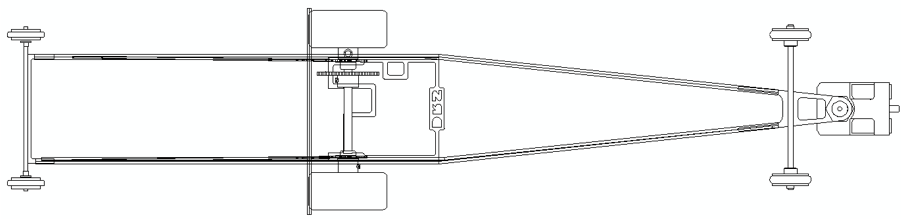

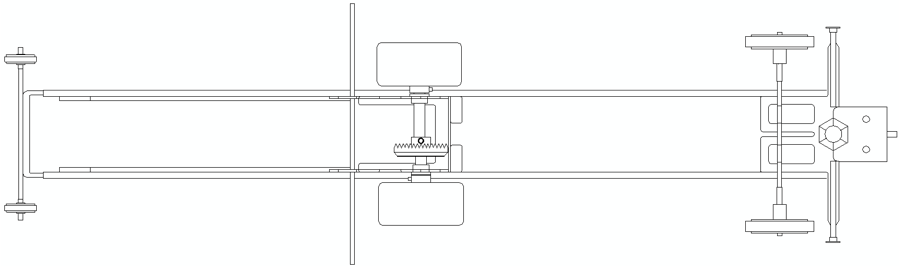

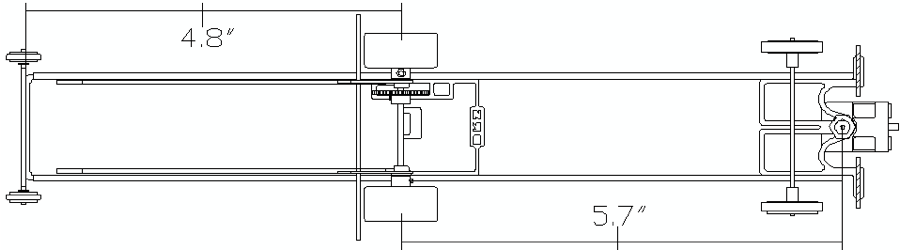

DRS 176 Pro-Inline Chassis Kit. For “Texas Style" Hardbody Racing.

We've heard your requests for a real Pro Type Inline Chassis for hardbody racing, and the DRS 176 is the first of several kits we've developed to respond to those needs The “Texas Style" of hardbody racing makes use of both normal and large, wide, "scale" tires on older, "nostalgia"-style bodies. As model kits of these cars are not as wide as later cars, and generally have a great deal of body tuck-under or curved sides, it makes tire clearance a major headache, even with existing sidewinder chassis and components. With the larger tires, an inline chassis is usually a necessity!

Until now, the choice has been limited in the selection of parts used in the construction of inline chassis. The popular choice has been the brass style, "U-shaped" bracket that fits the rear axle, and has a provision for a screw in motor. This is a stamped and folded piece that can have any number of problems, such as poor alignment of the rear axle (makes the car dog track as it goes down the drag strip) and most importantly, the alignment of the motor and axle! When the motor and axle are not aligned properly, it make a good gear mesh impossible. The axle and motor shaft MUST mounted at the same height.

The first advantage of the DRS 176 solution is the front nose piece. It allows, depending on body type and personal preference, the front of the body to be mounted at two points: straight off the front, or to the sides of the nose. It also has an adjustable front axle mount, and full .050" steel protection for the guide flag, which allows the use of a incredibly wide range of bodies, from muscle car favorites of the '60s and '70s all the way back to Gasser models of the '30s and '40s! And, of course, it will also work equally well with those lexan bodies that have been hard to use with a conventional sidewinder setup.

The DRS 176 chassis features a sturdy, precision .050" steel Motor Tab to mount your motor with screws, and rest assured, our motor tab and pillowblocks are exactly aligned properly for maximum performance. The pillowblocks are sized for 3/32nd axles. No more adapters, and Ball Bearings are now easy to use!

The rear of the body may be mounted with a solid or "floater" tube at the chassis balance point, at the forward, higher upright hole, or the slightly lower rear hole (as shown). Holes are large enough to permit proper "float" with either .050" or .062" tubing. Used with our Stainless Steel Chassis Tubing (DRS-162) this chassis will fit any 1/24th 1/25th chassis that I can think of. It even fits the Thames Panel Truck - with .350” wide tires!

DRS-177 Pro Top Gun Chassis Kit .025" Material!

I have been racing in a series that runs Top Gun at a 70 gram minimum weight. I found that with my current chassis kits, and using a Studebaker body, the lightest I could get a car without serious modification was about 74-78 grams. Well, with this kit, the same style chassis and body, my car came in at 66 grams ready to race!

If you're looking for a light C-Can chassis, here's your answer! The DRS 177 kit is cut from .025" material, versus the normal .050" material. I also trimmed and hollowed out the individual components in every place that would not compromise the strength or durability of the chassis.

You'll also notice that it comes with a rear wheelie mount that slides into the end of our DRS 161 chassis tubing. This save the hassle of bending this piece from .047' wire. I set mine up with a 4.750" long wheelie bars, then used 4.0" wheelie bar braces. The angle of the wheelie bar brace slots in the pillowblocks are set at this length and angle.

DRS 178 Scale Tire Pro-Inline Chassis Kit.

For “Texas Style" Hardbody Racing.

We've heard your requests for a real Scale Tire Pro Type Inline Chassis for hardbody racing, and the DRS 178 is the second of several kits we've developed to respond to those needs The “Texas Style" of hardbody racing makes use large diameter, wide, “scale" tires on older, "nostalgia"-style bodies. As model kits of these cars are not as wide as later cars, and generally have a great deal of body tuck-under or curved sides, it makes tire clearance a major headache, even with existing sidewinder chassis and components. With the Scale Tires, an inline chassis is usually a necessity!

Until now, the choice has been limited in the selection of parts used in the construction of inline chassis. The popular choice has been the brass style, "U-shaped" bracket that fits the rear axle, and has a provision for a screw in motor. This is a stamped and folded piece that can have any number of problems, such as poor alignment of the rear axle (makes the car dog track as it goes down the drag strip) and most importantly, the alignment of the motor and axle! When the motor and axle are not aligned properly, it make a good gear mesh impossible. The axle and motor shaft MUST mounted at the same height.

The first advantage of the DRS 178 solution is the front nose piece. It allows, depending on body type and personal preference, the front of the body to be mounted at two points: straight off the front, or to the sides of the nose. It also has an adjustable front axle mount, and full .050" steel protection for the guide flag, which allows the use of a incredibly wide range of bodies, from muscle car favorites of the '60s and '70s all the way back to Gasser models of the '30s and '40s! And, of course, it will also work equally well with those lexan bodies that have been hard to use with a conventional sidewinder setup.

The DRS 178 chassis features a sturdy, precision .050" steel Motor Tab to mount your motor with screws, and rest assured, our motor tab and pillowblocks are exactly aligned properly for maximum performance. The pillowblocks are sized for 3/32nd axles. No more adapters, and Ball Bearings are now easy to use! The rear of the body may be mounted with a solid or "floater" tube at the chassis balance point, at the forward, higher upright hole, or the slightly lower rear hole (as shown). Holes are large enough to permit proper "float" with either .050" or .062" tubing. Used with our Stainless Steel Chassis Tubing (DRS-161) this chassis will fit any 1/24th, 1/25th chassis that I can think of. It even fits the Thames Panel Truck - with .350” wide tires!

Funny Car Length

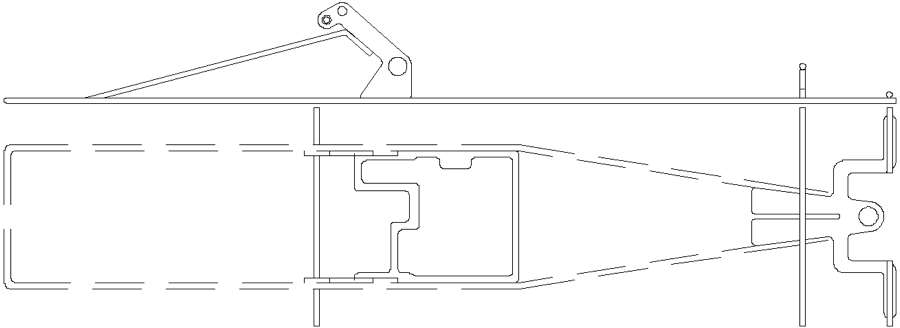

DRS-179 The “Silencer” AA/Fuel Coupe or Pro-Stock Chassis

Material List for this kit built to AA/FC Specifications using the DRS 511 Corvette Body.

One piece of .072” DRS-161 Chassis Tubing 2.0” long (rear support tube). Two pieces of .072” DRS-161 Chassis Tubing 10.5” long (main chassis tubes). One piece of DRS-146 .050” Pin Tubing two and one half inches long (rear body mount tube). One piece of DRS-146 .050” Pin Tubing 1.55” long (front axle tube). One piece of DRS-146 .050” Pin Tubing 2.08” long (front body mount tube). Two pieces of .050” Pin Tubing or .047” piano wire 4.0” long (wheelie bar braces).

We Recommend Race Tested and Approved Genuine Drag Racing Specialties Parts to Complete Your Rolling Chassis. DRS-511 Corvette Body, DRS-134 Guide Flag and Nut, DRS-132 Drag Braid, DRS-149 Drilled .500 Front Wheels, DRS-142 .047 Retainers, DRS-138 Wheelie Bar Axle

Tuning the chassis comes from the length of the rear support tube. The rear body mount tube slides inside of the rear support tube. When you cut the rear support tube 2.0” long you will find that it will be flush with the outsides of the pillowblocks. In this configuration, the chassis will be quite flexible when the body is mounted.

If you lengthen the rear support tube to the same length as the rear body mount, you will find when the body is mounted, the chassis will be quite stiff, due to lack of flexibility in the rear body mount tube. Trimming back the rear support tube exposes more of the rear body mount tube, in turn this will allow complete tuning of the chassis flex.

DRS-180 Sidewinder, Screw in Motor Wire Chassis Kit.

This chassis is similar to DRS-166 Chassis Kit. The major difference is that it has a screw in motor provision. The chassis can be built for Doorslammers or Funny Cars. You just pick which axle configuration, large wheels for the Doorslammers and small wheels for the Funny Cars.

We recommend race tested and approved Genuine DRS parts to complete your Rolling Chassis. DRS-134 Guide Flag And Nut, DRS-132 Drag Braid, DRS-148 .820 Drilled or DRS-124 Undrilled Front Wheels for Doorslammers, DRS-149 .500 Drilled or DRS-125 Undrilled Front Wheels for Funny Car, DRS-161 Chassis Tubing (2 required), DRS-146 .050 Stainless Steel Pin Tube (3 required), DRS-142 Retainers, DRS-138 Wheelie Bar Axle With Wheels

DRS-181 "Sliding Ballast" Nitro Sidewinder Chassis Kit .025"

This chassis, although similar to DRS-180 is unique with its ability to easily move the weight bar forward and aft. This changes the balance point of the chassis. More weight on the braid or the rear tires is now easily attainable. This chassis also has a provision for a screw in motor mount. Unlike the DRS-180 you can use this feature or not. For those wishing to know, We always prefer to solder in the motor, not mount it with screws. This chassis is our chassis of choice for Hard-body Racing as with an average body, you can build a car at about 90 grams. In SDRA Drag Racing this gives us around 30 grams of ballast to put where we want it on the chassis for optimum performance. We recommend race tested and approved Genuine DRS parts to complete your Rolling Chassis. DRS-134 Guide Flag And Nut, DRS-132 Drag Braid, DRS-148 .820 Drilled or DRS-124 Undrilled Front Wheels for Doorslammers, DRS-149 .500 Drilled or DRS-125 Undrilled Front Wheels for Funny Car, DRS-161 Chassis Tubing (2 required), DRS-146 .050 Stainless Steel Pin Tube (3 required), DRS-142 Retainers, DRS-138 Wheelie Bar Axle With Wheels, TQ Drag Wire.

DRS 190 Scale Tire Hardbody .025” Pro-Stock Inline Chassis Kit

We've heard your requests for a real Scale Tire Pro Type Inline Chassis for Hardbody Pro Stock racing, and the DRS 190 is one of several kits we've developed to respond to those needs The "California Style" of hardbody racing makes use large, wide, "scale" tires on older, "nostalgia"-style bodies. As model kits of these cars are not as wide as later cars, and generally have a great deal of body tuck-under or curved sides, it makes tire clearance a major headache, even with existing sidewinder chassis and components. With the Scale Tires, an inline chassis is usually a necessity!

Until now, the choice has been limited in the selection of parts used in the construction of inline chassis. The popular choice has been the brass style, "U-shaped" bracket that fits the rear axle, and has a provision for a screw in motor. This is a stamped and folded piece that can have any number of problems, such as poor alignment of the rear axle (makes the car dog track as it goes down the drag strip) and most importantly, the alignment of the motor and axle! When the motor and axle are not aligned properly, it make a good gear mesh impossible. The axle and motor shaft MUST mount at the same height. The first advantage of the DRS 190 solution is the front nose piece. It allows, depending on body type and personal preference, the front of the body to be mounted at two points: straight off the front, or to the sides of the nose. It also has an adjustable front axle mount The 190 Allows the use of a incredibly wide range of bodies, from muscle car favorites of the '60s and '70s all the way back to Gasser models of the '30s and '40s! And, of course, it will also work equally well with those lexan bodies that have been hard to use with a conventional sidewinder setup.

The DRS 178 chassis features a sturdy, precision .025" steel Motor Tab to mount your motor with screws, and rest assured, our motor tab and pillowblocks are exactly aligned properly for maximum performance. The pillowblocks are sized for 3/32nd axles. No more adapters, and Ball Bearings are now easy to use! The rear of the body may be mounted with a solid or "floater" tube at the chassis balance point, at the forward, higher upright hole, or the slightly lower rear hole (as shown). Holes are large enough to permit proper "float" with either .050" or .062" tubing. Used with our Stainless Steel Chassis Tubing (DRS-161) this chassis will fit any 1/24th 1/25th chassis that I can think of. It even fits the Thames Panel Truck with .350” wide tires!

DRS-193 Kit Genuine Gunslinger AA/FC Chassis by Bob Herrick

Assembled Weight approximately 10-11 grams! “YES, WE MEAN ASSEMBLED WEIGHT!”

The Gunslinger Chassis represents the finest example of High Technology in Slotcar Racing today! You will have no doubt in your mind when you pick up and look over one of these Crown Jewels that you are looking at the finest Chassis available at ANY PRICE. The attention to detail is simply nothing short of INCREDIBLE.

First we starts with a Specially Designed Motor Box and Strut Assembly, then fabricate the outer rails from Hollow Stainless Steel Tubing.

The Common misconception is that a lighter car is better. Fact: fragile lightweight cars do not win the "Big Races" and all the cars that are holding The World Records along with winning the big races have been weighing between 50 to 57 grams. We are using Hollow Tubing to allow a more rigid Chassis for BOGG Glue Racing that has become common at the "Big Races".

We were building the 37 to 50 gram cars back in the 80's and quickly learned that this type of car will on occasion will make a good pass, after much lane preparation. Put that same car on the line at a "Big Race" with 60 seconds to stage with varying glue conditions and you will soon be watching the race from the sidelines, much less not having a chance to set the record!

We have seen it all, done it all, and are willing to share our experience with each and every customer.